Preparation of the REAL for M2HATS

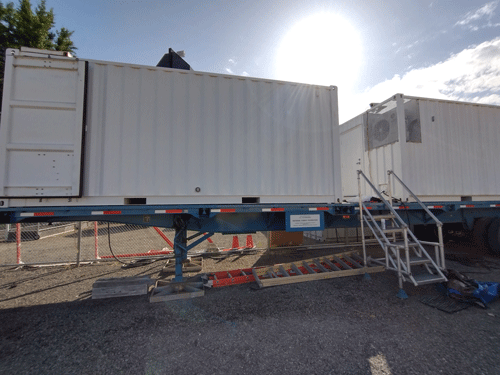

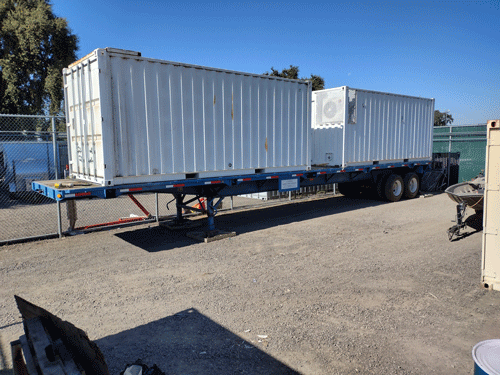

July 8, 2023: The REAL is packed and ready to ship on July 9 to Tonopah, NV.

June 28, 2023: Dexter Rowland and Ben Crane, from NCAR EOL, came to Chico to help prepare the REAL for shipment to M2HATS.

June 22, 2023: Brian Gardner (FMS) loading two new tool chests into the REAL.

June 20, 2022: Twice since using the LG air conditioner this year (May 7 and June 13) we found a small flood on the floor of the rear container. A service call from Lugenbeel Mechanical today concluded that the condensation drain hose from the interior blower had become disconnected.

June 14, 2023: The area previously under the jib crane base plate was scrubbed with dish soap and water today. Next step will be to apply rust-stopper in a few areas and touch up with white paint. Also, the BSU has been removed and the hatch covered with a plate.

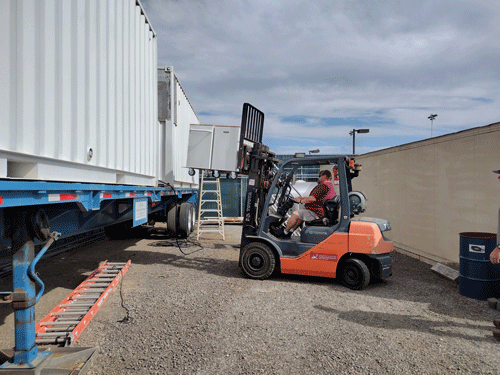

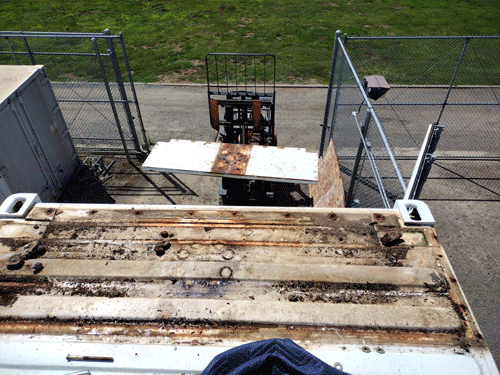

June 14, 2023: (Below) Jib crane base plate removed from lab container today. 12 years of dust, rust, and wasps nests underneath. Thanks to Brian Gardner with Facilities Maintenance Services for expert use of the forklift and Jaydie Lee of College of Natural Sciences for help getting the bolts off!

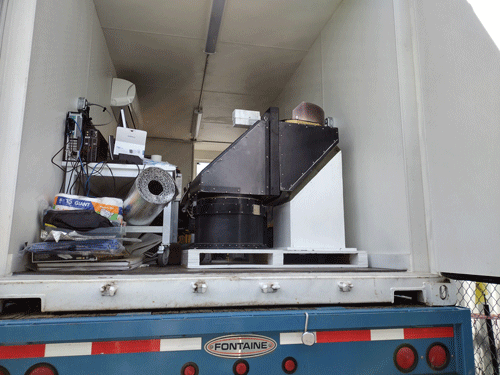

June 14, 2023: Beam steering unit moved to rear container for transport to Tonopah, NV. Sorry I don't have good picture of forklift doing the move. Was busy directing.

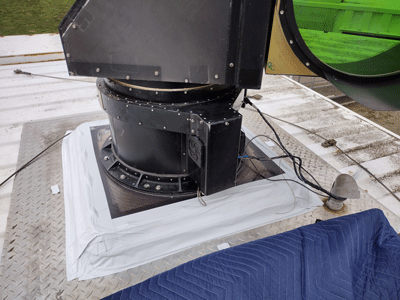

June 13, 2023: Beam steering unit (BSU) on pallet and ready for forklift ride down and into rear container. Thanks to Jaydie Lee, Bill Koperwhats, and Eric Ayars for lifting the pallet on to the roof and moving the BSU over to the pallet.

May 23, 2023: Justin Hicks and Shane Mayor scrubbed the roof and a couple exterior walls of the lab container today, and applied some paint to surface rust. Before and after below.

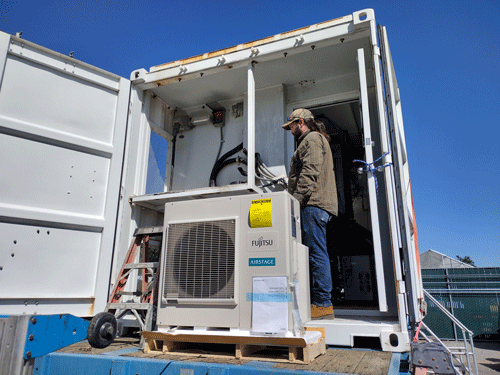

May 10, 2023: Lugenbeel Mechanical installed a new air conditioning system on the lab container today. A 3-ton Fujitsu Halcyon. Should last the next 20 years.

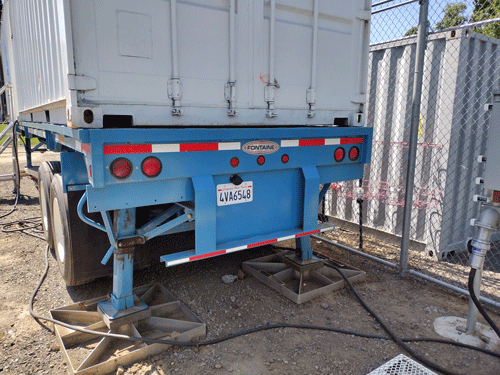

April 27, 2023: Finally got a license plate for the trailer today. The trailer is registered to Chico State Enterprises, a non-profit LLC that manages grants and contracts on behalf of California State University Chico.

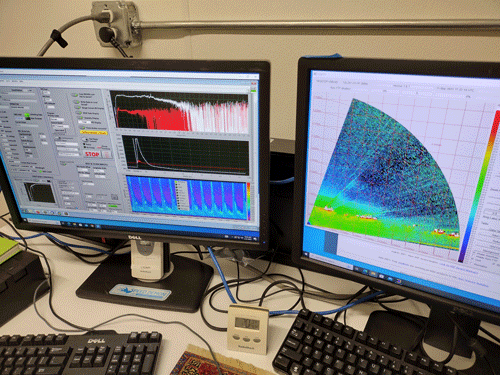

March 31, 2023: We observed the growth of the atmospheric boundary layer and the bases of cumulus clouds this morning with RHI scans. We were able to see some aerosol structures to ranges beyond 5 km when pointed at the lowest elevation angles. Will try to make some better images when time allows.

March 30, 2023: A cool and humid start to the morning resulted in lots of condensation on the inside of the scanner window. After clearing it, the REAL collected nearly horizontal PPI scans today looking to the north. Conditions were quite clear but we saw aerosol structures to ranges just beyond 2 km. Will try to make and post some images of the data when time allows.

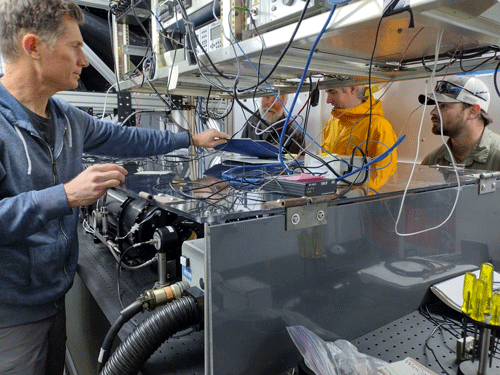

March 28-30, 2023: Full house with Dr. Scott Spuler, Mr. Bruce Morley, Dr. Robert Stillwell, and Mr. Ben Crane --- from the National Center for Atmospheric Research (NCAR) Earth Observing Laboratory (EOL) assisting. Steady rain on Tuesday morning (0.8") and all day Wednesday (0.6") made the work challenging.

March 27, 2023: Rain water has been leaking into the lab container from around the beam steering unit (BSU). Today, Bruce and I removed the BSU, cleaned the gasket, attached the BSU with new stainless bolts, and added additional extra wide Gorilla tape around the channel between the top of the BSU tower and the roof of the container. Unfortunately, it didn't stop the leak completely and a tarp is being used to help drain rain water off of the roof. Someday, the whole assembly from the steel diamond plate up should be removed, resealed, and reassembled.

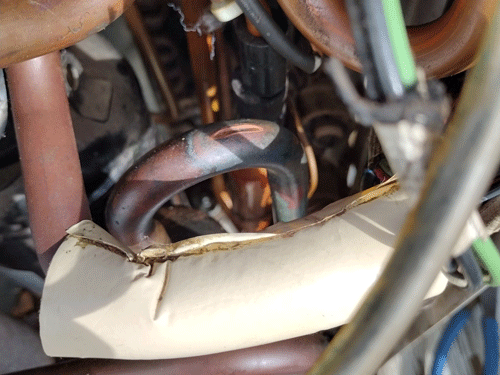

March 25, 2023: Paul Lugenbeel discovered a leak in the air conditioning system where an electrical wire was rubbing on a copper pipe (shown below). The insulation on the wire was worn off and the bare copper wire rubbed a groove in the copper pipe until it leaked. It is likely that this occurred over many years. Fortunately, Paul was able to solder the hole and recharge the system. Given the age of the air conditioning system (about 16 years) and its importance, it is clear that we need a new one.

March 23, 2023: After 14 years at the University Farm, the laboratory shipping container roof accumulated a layer of mold or algae. Today I started scrubbing it off with a battery powered scrubber and dish soap and got perhaps 25% of it done. More importantly however, Bruce got the Nd:YAG pump beam through the Raman cell at low power.

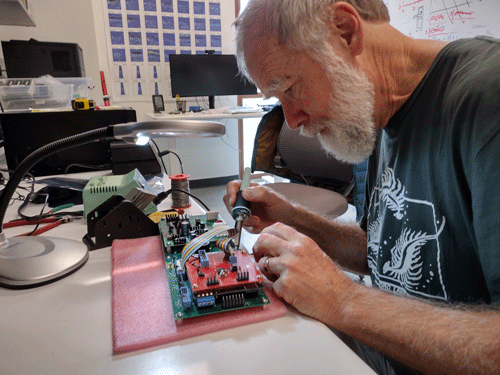

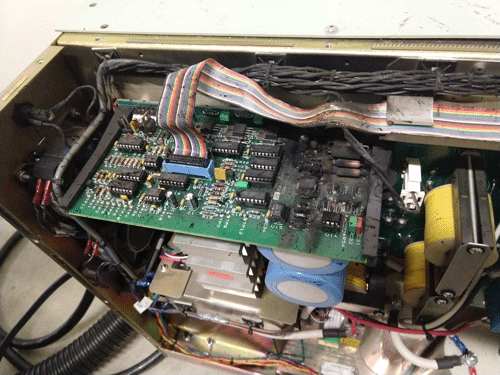

March 22, 2023: We found a female BNC jack connector, used for the shot single button, had separated from the control board on the power and cooling unit of the Nd:YAG laser. We ordered a new one with overnight shipping through Digikey. Bruce Morley repaired the board.

March 9, 2023: Bruce Morley from the National Center for Atmospheric Research (NCAR) visited us and started working on preparing the instrument for M2HATS. Thanks to Bruce, we installed the system control and data acquisition computer and Nd:YAG laser, calibrated the scanner for pointing, and got subsystems like UPSs and PDUs communicating on the local network. Bruce is scheduled to return to Chico on March 20.

February 22, 2023: Paul Lugenbeel recharging the laboratory container's Fujitsu Halcyon (Model AOU36RML) 36,000 BTU heat pump.

February 21, 2023: The REAL uses 5 APC rack-mounted smart-UPSs (uninterruptible power supplies) (4x120V and 1x240V) to keep the lidar running during brief power outages. Today 48 lead-acid batteries (12V 5Ah) were changed. Each 120V UPS has 8 batteries and the 240V UPS has 16.

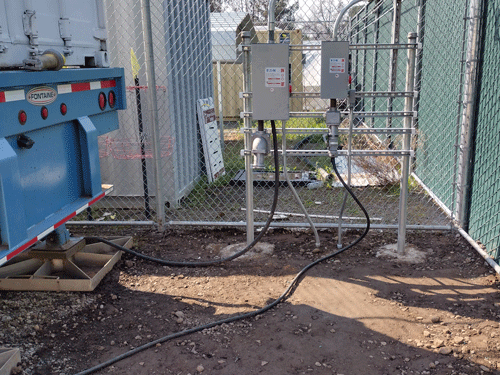

February 10, 2023: Electrical power connected and turned on. Still missing some fuses, but electricians by-passed them given there are fuses elsewhere in the circuit.

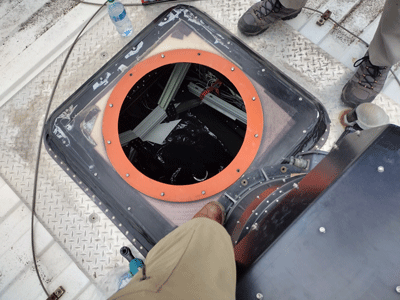

February 9, 2023: Installed beam steering unit (BSU) on roof of container. Link to exciting Youtube movie.

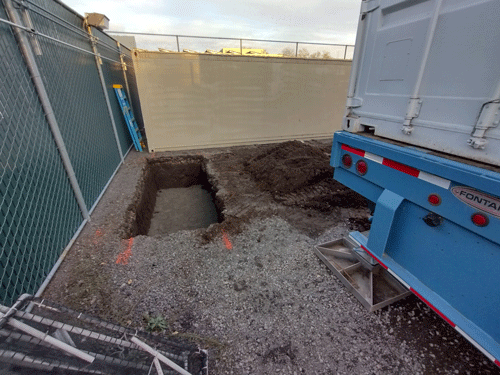

February 2, 2023: Ufer pit was filled in today and one electrical disconnect installed.

January 19, 2023: Concrete poured into Ufer pit and posts set for electrical panel.

December 23, 2022: A Ufer pit was dug today for an electrical ground that adheres to the National Electrical Code (NEC)

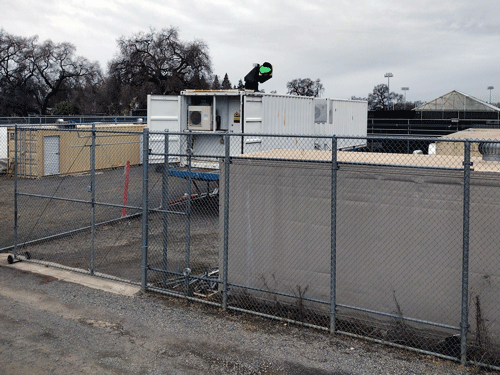

October 14, 2022: REAL moved to a spot on campus near the tennis courts and greenhouses. Unfortunately, no electrical power. Paperwork signed to install power in late November of 2022.

As of early October 2022, parked near the Irrigation Training Facility at the farm waiting to be moved to campus. All new tires and air brake chambers.

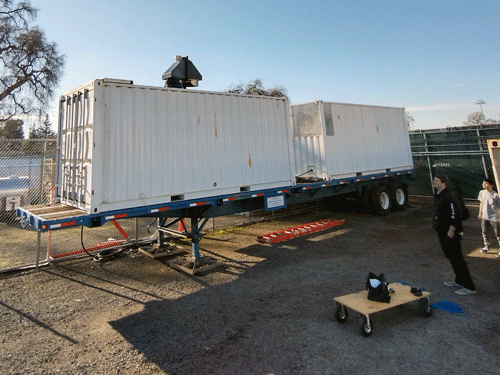

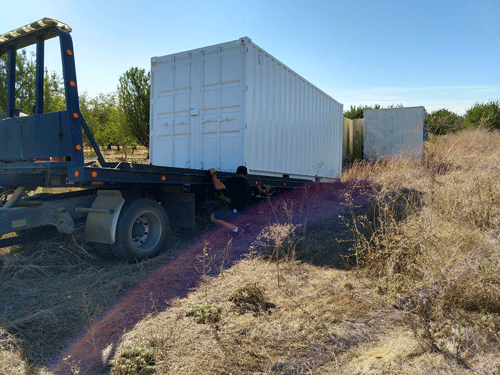

September 17, 2022: Mike's Crane Service removing the old container and installing the new one:

September 17: 2022: Day Enterprises moving the trailer off the berm:

September 15, 2022: Removal of the infamous jib crane:

May 6, 2022: (Below) A resistor on a circuit board went out with a bang in the power and cooling unit of the REAL's Nd:YAG pump laser (Continuum Surelite III). Jaydie Lee replaced the board. Additional boards were replaced to restore the 20 year old laser (valued at about $35K) to operational status.

Summer of 2021: Efrain Cobian (shown below) and Niko Merrick disassemble, clean, and reassemble the original REAL beam steering unit (BSU) under funding from CSC2.

October 26, 2019: (Below) A new shipping container from Container Solutions is delivered to replace the rear container on the REAL trailer. It is a finished container with insulated walls, a powerful air conditioning system, personnel door, interior lightning, etc. Unfortunately, we ran out of funding soon after it was delivered and were not able to replace the old wasp and mold infested container on the trailer until 2022.

Below: The shipping container on the rear of the trailer (the one over the wheels) had a very long and good life, but its days as a lidar container came to an end at Chico State. With a leaky roof and shag carpet walls, and countless holes and cracks in the walls, it became infested with mold and wasps.